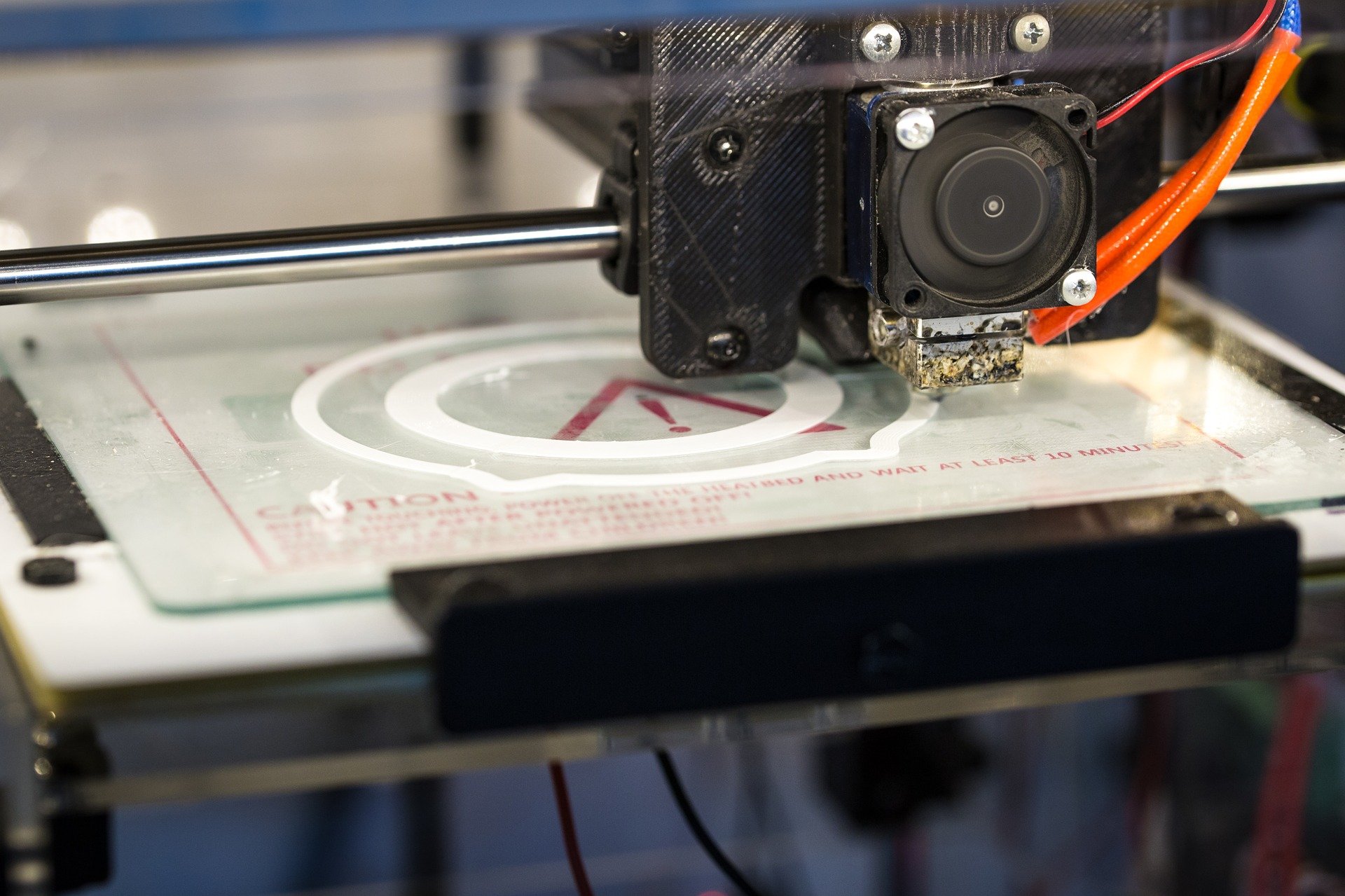

Every technology has its limits. 3D printing is not exempt from this principle. After the advent of technology, there was a lot of hype about the fact that you could print almost anything you could imagine: food, weapons, glasses, and things that deal with a certain topic or brand or your choice. While we’re moving in a direction where more and more things are being 3D printed by customers, many things won’t be able to be 3D printed in the not-too-distant future. Therefore in this post, here are some of the few things that can’t be printed with 3D printing.

Remember that 3D printers have limitations in terms of accuracy. The typical nozzle output is about 0.4 mm. So, if you plan to print anything below 0.4 mm, you won’t get a decent part. 0.4 mm is great for a variety of today’s consumer products. However, if you want to replace very small objects, like a broken camera or a broken nylon gear in a camera, then you definitely won’t be successful with 3D printing. There is a new technology called selective laser sintering that can be used to manufacture fairly accurate products. However, it is still not very beneficial for making very small parts.

Remember that 3D printers have limitations in terms of accuracy. The typical nozzle output is about 0.4 mm. So, if you plan to print anything below 0.4 mm, you won’t get a decent part. 0.4 mm is great for a variety of today’s consumer products. However, if you want to replace very small objects, like a broken camera or a broken nylon gear in a camera, then you definitely won’t be successful with 3D printing. There is a new technology called selective laser sintering that can be used to manufacture fairly accurate products. However, it is still not very beneficial for making very small parts.

Let’s take an example: you want to print a broken part of your vacuum cleaner? Where do you start printing? You may need to know computer-aided design and figure out the exact part that is broken. Some of the scenarios that will be checked are the dimensions of the part to be printed along with the aesthetics of the object. These elements are difficult to reproduce if you are not an expert in 3D printing. If you don’t have a design, you can’t print anything. Also, the part you want to print must be suitable for 3D printing. You can’t print things that don’t have some horizontal parts or that have very large protrusions. Because of the way a nozzle or syringe is used to print items, you cannot print large protruding parts without the parts falling off during the printing period.

Few things can be 3D printed. Although technology is growing and many more materials may be used in the future, some things cannot be printed because there is no suitable material. Most printable substances are substances that can be brought to a semi-melted state so that they can fit comfortably in the nozzle. Almost all of these substances are low melting temperature plastics, metals, and many types of pastes. Other than that, there are not many materials that can be used.

3D printers are limited in their production speed. You may need to purchase hundreds of 3D printers inside the marquee, which is not possible. If you own a business and want to switch your production from conventional manufacturing to 3D printing, you may have to start with limited edition items and small batch production. Otherwise, 3D printing technology is not yet advanced enough for mass production.

It is not difficult to change the 3D design on your desktop, but it is difficult to feel a 3D printer that meets the new requirements. Printing 3D objects require extensive knowledge of algorithms and applications. They are not easy to consume. All it takes is a little bit of fiddling with settings to get a very different product than you intended. Hardware installation can be challenging and requires experience. Because of this, you may not be able to create certain items from time to time if you require modifications to your 3D printer.

It is not difficult to change the 3D design on your desktop, but it is difficult to feel a 3D printer that meets the new requirements. Printing 3D objects require extensive knowledge of algorithms and applications. They are not easy to consume. All it takes is a little bit of fiddling with settings to get a very different product than you intended. Hardware installation can be challenging and requires experience. Because of this, you may not be able to create certain items from time to time if you require modifications to your 3D printer.